The difference between wire wound resistance and metal film resistance

Introduction of wire wound resistance:

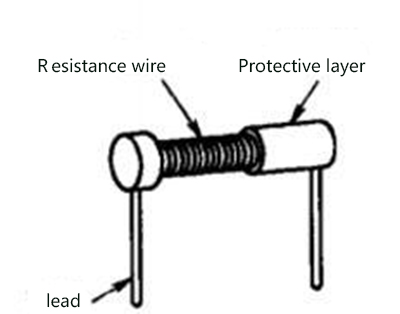

Wire-wound resistors are made of constantan, manganin or nickel alloy wire wound on a ceramic skeleton, with protective paint or glass glaze on the surface. There are two types: fixed and adjustable.

Wire wound resistors are one of the more commonly used resistors. The resistance body of the wire wound resistor is a resistance wire. The resistance wire is wound on the ceramic frame, the lead is connected, and the surface is coated with a layer of glass glaze or insulating paint to make the wire wound resistor.

Winding resistance characteristics:

A: Non-flammable wire-wound coating resistors

B: Can withstand high pressure shock

C: Faster heat dissipation

D: In a short time

E: Low noise

F: Resistance has not changed for many years

G: The error range is small, ±5%, ±2%, ±1%

H: Power range: 1/2W-10W

Advantages and disadvantages of wire wound resistors:

The advantages and disadvantages of wire-wound resistors include high resistance accuracy, low noise, stability and reliability, but large size and relatively large capacitance inductance. For detailed advantages and disadvantages, please refer to another article about wire wound resistor.

Application areas of wire wound resistors:

Wire-wound resistors are mainly used to reduce voltage, shunt, load, feedback, transfer energy, and match in low-frequency AC circuits, or act as absorbers and voltage dividers in power circuits, and can also be used as The attenuation adjustment in the oscillating circuit and the transformer and the shunt in the pulse forming circuit.

In addition, it can also be used for discharge and spark suppression of filter stage capacitors in rectifiers. It is also widely used in household appliances, medical equipment, automobile industry, railway, aviation, military equipment and other fields.

Introduction of metal film resistors

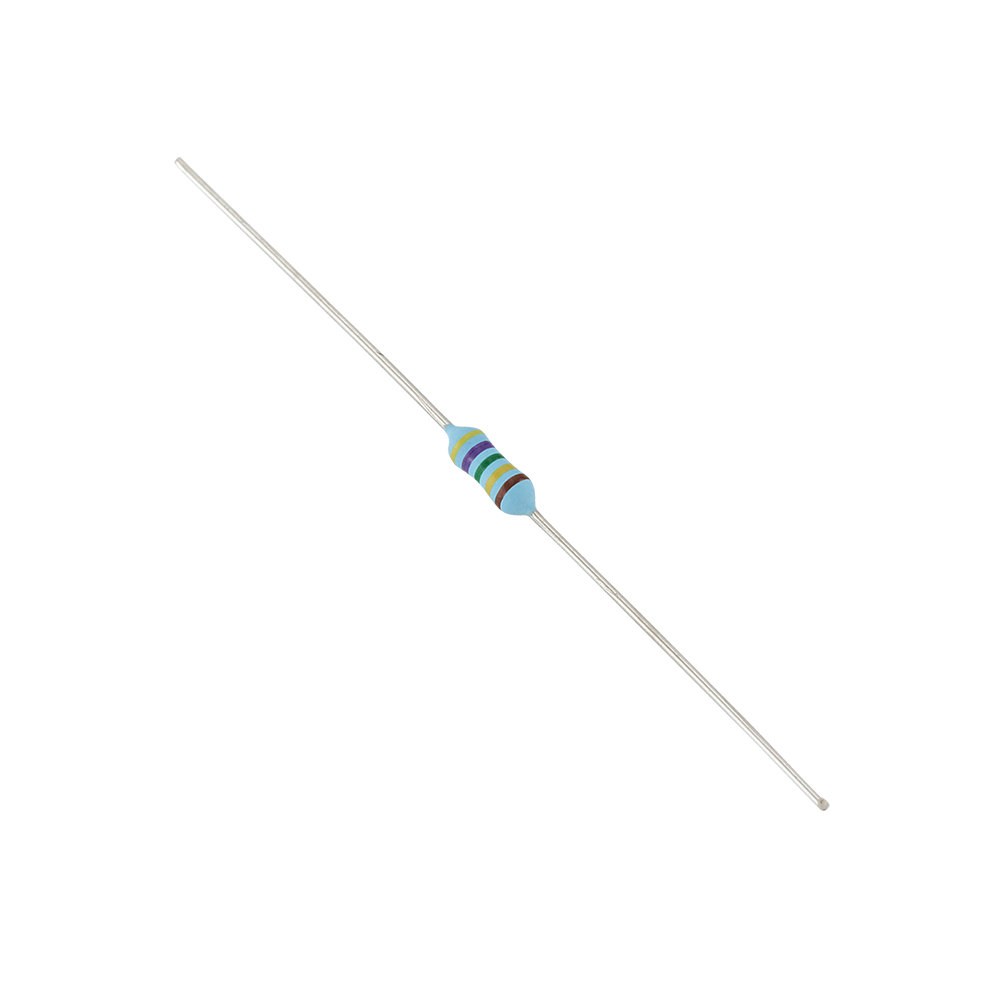

Metal film resistors are a type of film resistors. It uses high-temperature vacuum coating technology to closely adhere nickel-chromium or similar alloys to the surface of the ceramic rod to form a film. After cutting and adjusting the resistance, it can achieve the final required precision resistance. , Then cut with appropriate joints, and coat the surface with epoxy resin for sealing protection.

Because it is a lead type resistor, it is convenient for manual installation and maintenance, and is used in most household appliances, communications, and instruments.

Performance parameters of metal resistors:

Temperature coefficient: ±100PPM/°C

Large power load, low current noise

High stability, good high frequency performance

Operating temperature range: -55°C-155°C

Accuracy: 0.25 [%], 0.5 [%], 1 [%], 5 [%]

Resistance range: 1Ω~10MΩ

Nominal resistance: E-96

Features of metal resistors:

A: High thermal conductivity porcelain core

B: High stability metal film

C: High insulation and solvent resistant epoxy paint

D: Meet the standards set by MIL&EIA

E: Good solderability

The difference between wire wound resistors and metal film resistors:

1. The metal film resistor heats the alloy in a vacuum, and the alloy evaporates, so that a conductive metal film is formed on the surface of the porcelain rod. The resistance value can be controlled by changing the thickness of the metal film. Compared with carbon film resistors, this type of resistor has the advantages of small size, low noise, and good stability, but the cost is higher. Metal film resistors are bright in color and can be subdivided into multiple types of high frequency, high voltage, and precision. Most applications are in high precision requirements.

2. Wire-wound resistors have accurate resistance, stable operation, low temperature coefficient, good heat resistance, large power but small resistance, large distributed inductance and distributed capacitance, and high production costs. It is suitable for low frequency and high precision circuits.

评论

发表评论